Sustainable Impact

Mitigating climate change is a many-sided mission.

We don’t claim to have all the answers, but we want to play our part.

Our products have the potential to achieve further circularity in the paper industry. As well as replacing some plastic packaging.

And cutting carbon emissions from landfilling coated paper products.

Sustainability

When developing our products, we’ve focussed on fulfilling key UN Sustainable Development Goals (SDGs).

The SDGs are part of the 2030 Agenda for Sustainable Development. They provide “a shared blueprint for peace and prosperity for people and the planet, now and into the future.”

Take a look at key SDGs we’re pursuing at Earthodic.

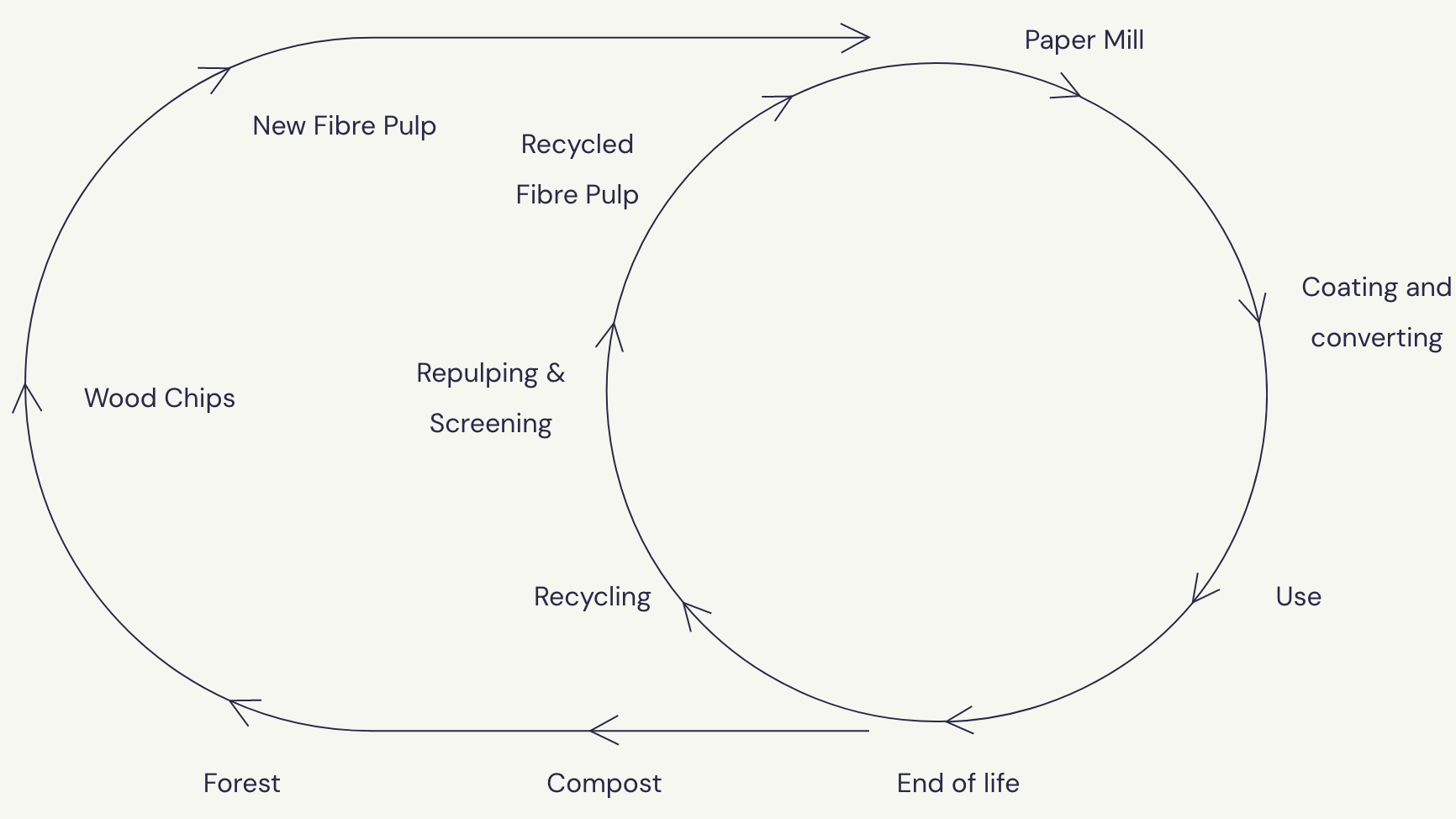

Circular flow of materials

BiobarcTM helps companies move away from a linear model where products are made, used and sent to landfill.

By protecting the substrate material and allowing a high percentage to be reclaimed, companies can extract value from their waste. And preserve the earth’s raw materials.

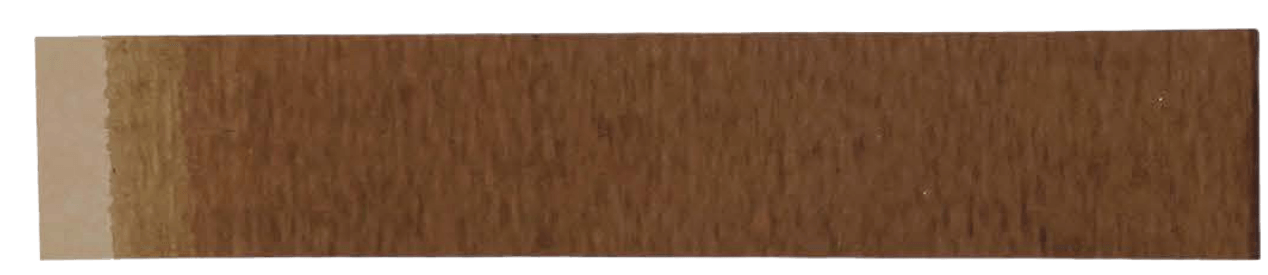

Repulpability

Repulpability specifically refers to the ability to turn paper back into pulp.

Traditional coatings can prevent this.

We’ve specifically developed BiobarcTM to allow paper and card to be repulped.

BiobarcTM coated paper has achieved 97.1% fibre yield on a standard 205gsm (42#) linerboard. 85% fibre yield is considered acceptable in the US whilst 95% is required in Europe.

We worked with Western Michigan University to test according to the Fibre Box Association (FBA) Voluntary Protocol Part I.

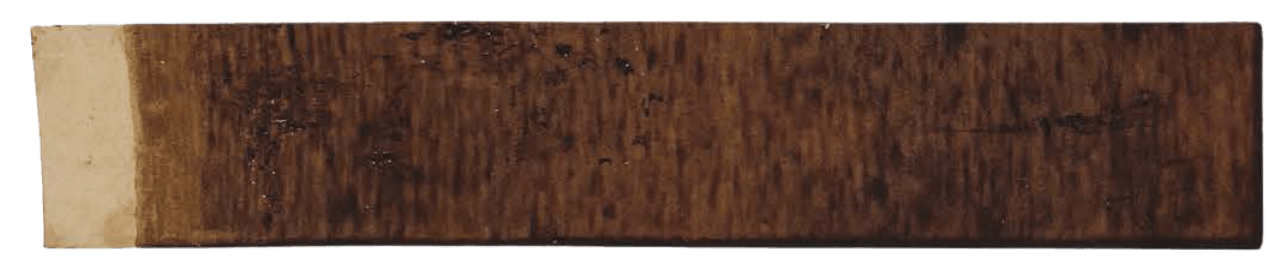

Recyclability

Recyclability is the ability for a material to be processed back into the same or similar raw material after use.

Globally, paper already has a high rate of recycling (68%) in comparison to plastic.

Our coating protects paper during use and allows for a high level of fibre recovery. Making recycling viable. Each tonne of cardboard that’s recycled because it’s coated with BiobarcTM captures and stores the same amount of CO2 as 3.7 acres of forest in 1 year.

We worked with Western Michigan University to test according to the Fibre Box Association (FBA) Voluntary Protocol Part II.

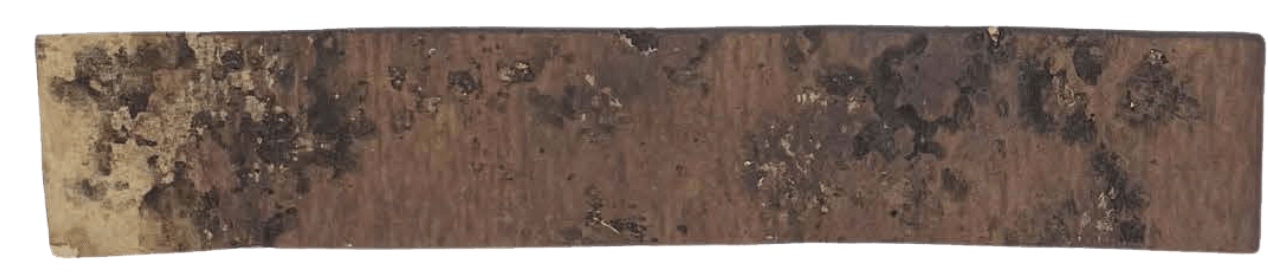

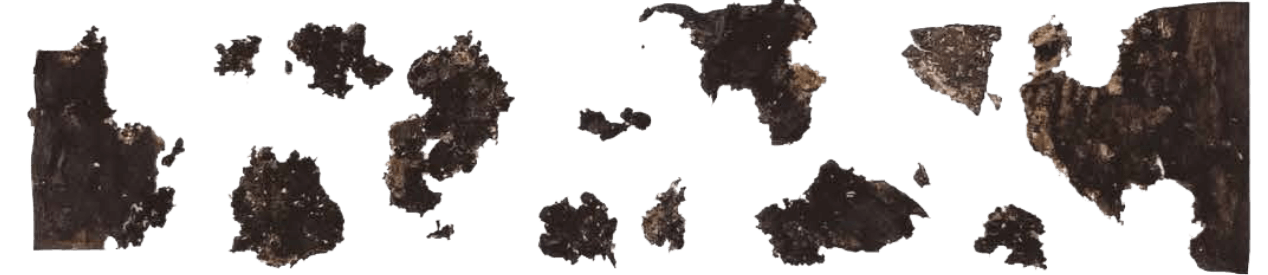

Compostability

Compostability means a material can be broken down by bacteria, fungi, or other biological means into hummus (nutrients for the soil).

When we tested our coatings in our home compost, they fully broke down.

And we’re in the process of getting third-party tests for both home and industrial compostability.

Biobased

Bio-based refers to materials derived from living organisms (either plant or animal). Whether used in natural form or synthesised.

All our products are certified as 100% bio-based carbon by the USDA BioPreferred program.

This tests that the carbon they contain comes from renewable resources–and not from petroleum or fossil-derived sources.

Industry perspective

Ben Lindsay, Investment Manager at Investible

Contact us

If you’d like to learn more about us or our products, please get in touch.

Whatever stage you’re at in your circularity journey, we’re here to help.

- hello@earthodic.com

- 18 Morrisby St

Geebung QLD 4034

Australia

"*" indicates required fields

- hello@earthodic.com

- 18 Morrisby St

Geebung QLD 4034

Australia